Enhancing Butt Welding machine with Advanced Data logger

Data recorders are essential when integrated with hot-melt butt welding machines, capturing and logging the welding process and pipe parameters. They play a crucial role in municipal and major engineering projects by ensuring consistent, high-quality welds.

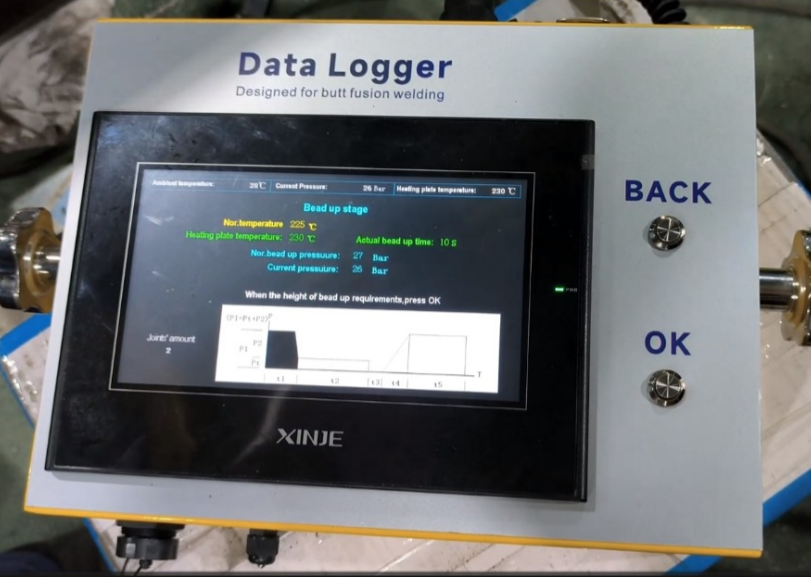

Data recorders log critical parameters such as temperature, pressure, and time, ensuring all welds meet specified standards. They document essential welding parameters, aiding in quality control and troubleshooting. In large-scale municipal and engineering projects, these records ensure regulatory and safety standards compliance. Modern data recorders can print welding records as small paper slips, facilitating easy storage and future reference.

Applications include municipal projects, where they ensure the safety and reliability of water and gas supply systems by maintaining high welding standards. In major engineering projects, they provide the necessary documentation to comply with stringent regulatory requirements. In industrial applications, they maintain high-quality welding standards in extensive piping systems, reducing downtime and ensuring reliability.

Data recorders, combined with hot-melt butt welding machines, significantly enhance the welding process. By recording critical parameters, providing detailed documentation, and offering printing capabilities, they ensure the success and reliability of municipal and major engineering projects, making them indispensable in modern welding operations.

Thank you for your reading.